| A break for the body. The front

grille

is duplicated by rubbing and pressing a 0.1 mm thick aluminium sheet on

the original part until all the contours are seen on the duplicate. The

grille rods are traced by a toothpick. Then the parts are taken apart

and

polyester putty (to be ground to better surface contour later) applied

at the back so that the part will have enough strength. |

|

|

| Now the story of the door hinges

begin.

A strip was cut from 0.2 mm brass sheet, with a width of 2.5 mm. One

side

was covered with a thin layer of solder. This will serve in holding the

metal together after the eye of the hinge is formed. The eye is formed

by squeezing the strip around a pin with the aid of pincers. |

|

|

| The eye is defined by pressing the

soldering

iron on the metal, thus melting the pre-soldered layer in between. |

.. ..

|

| The mid part of the eye is ground by

cutter

tip of Dremel to make recess for the mating part of the hinge. |

|

| The finished mating parts are shown

here.

The second part is made in the same manner as described above, but with

the difference that the sides of the eye are ground to leave the center

part to fit in the recess of its mate. |

... ...

|

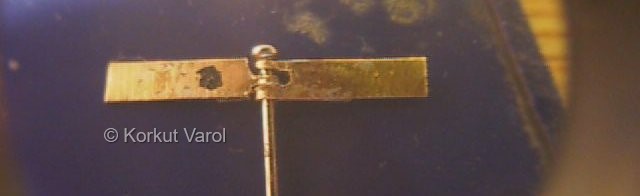

| The mating of the two parts of the

hinge

is shown here. The two leaves of the hinge will be cut to proper length

to fit in its place in the body. Two for each door, total of four

hinges

were made. |

|

| Preparing the hinges before

assembling

to the body. The working axes of the hinges are defined to be coaxial

by

using a common pin for assembly purposes. Later, the pin will be

replaced

by two separate ones. |

|

| The perpendicularity of the turning

axis

is checked before final glueing. 5-minute epoxy was used to fasten the

hinges to the body and doors. |

|

| A precaution was taken with masking

tape

in case the glue would stick to the other leaf of the hinge. They will

stay in place until the door is glued also. One good thing with these

hinges

is that the doors can be removed in the process of preparation for

painting,

and painting itself. |

|

| The doors are put in place (after

final

assembly testing with the hinges) and 5-minute epoxy glue applied to

the

doors, at the points where the hinges are. The doors were secured to

the

body with masking tape until the glue was dry. |

|

| A close-up of the hinge while drying.

Note that the masking tape used here is the protective cover of a

double-sided

transparent sticking sheet. The paper is waxed, so it is impossible for

any glue to stick to it. |

|

| Here it works! The excess part seen

on

the hinge was cut away with Dremel cutter tip. |

|

|

|