UPDATED

Dec.14,2000:

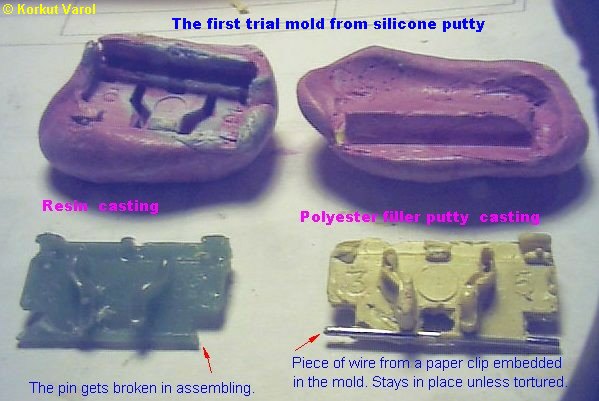

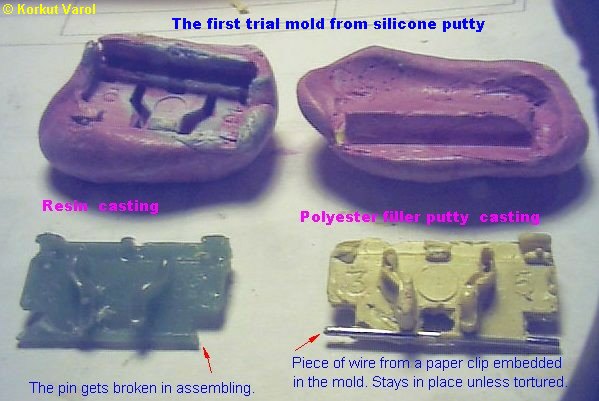

I began with

a trial mold made from 5-minute silicone putty. I cast a sample piece,

but the joint pins readily got broken due to brittleness. So I made

another

trial, this time I used polyester filler putty. I put a metal insert as

the pin from a piece of paper clip. This proved fine, the putty stuck

to

the pin and firm enough for a model.

|

|

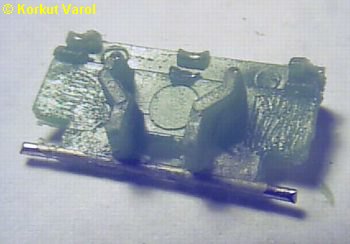

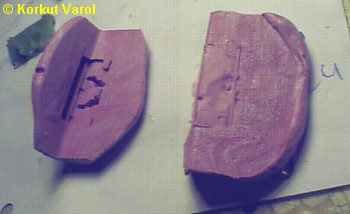

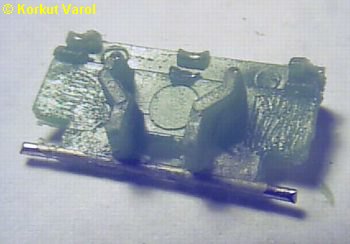

| I repeated casting

with resin, with the metal inserts. Still fine results. To make better

grips, the pins were roughened with filing. Here, you see a cascade

mounted. |

|

| And here, a cast

one is placed in the kit's original tracks. |

|

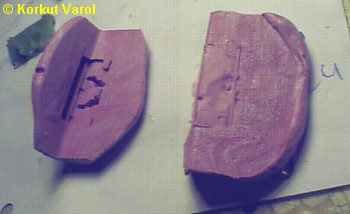

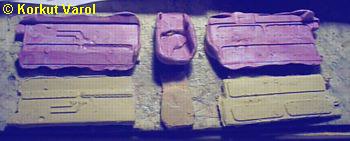

| Heading on for

better parts, I made a new mold, enabling good command on poured resin. |

|

| And here is a

sample from that mold. Following parts were better. |

|

| UPDATED

Dec.26,2000:

The geared wheels

were resin cast by the aid of a RTV silicone mold.

|

|

| For the piston

rod, a 2-piece mold was made from 5-min. silicone putty. Instead of

copying

the whole rod in resin (which had a risk of breaking), I put a polished

steel rod in the mold and cast the head with pins only. Nice job! |

|

| The big roller

wheel was copied by making an open half-mold. The one on the right is

resin,

and on the left is automotive polyester putty. Both resulted in good

pieces,

but the one from the putty had some gaps on it, since it was not liquid

prior to putting in the mold. But those holes can be filled easily, so

it was no problem. |

|

| Here, the two

are joined by superglue to form a wheel unit. |

|

UPDATED

Jan.10,2001:

The hood was

done with foil-copying and using it as a mold. |

|

My resin stock

ended, and not being able to find the brand I used, I tried other

materials

for casting. The molds were made from silicone mold putty from here on.

These parts

were

cast from 5-minute epoxy. Took a few days to harden fully. |

|

| So were these

transparent parts, except for the dark gray ones below. They were done

from metal epoxy. The white styrene pieces you see within the cast

command

console are embedded in the resin fill up volume and save resin. |

|

| This left outer

wheel and track holder was cast from the last remainders of resin. |

|

| The pulleys and

belts were duplicated by using automotive polyester putty. The

difficult

part is that since it is not liquid, you cannot be sure if it goes to

every

point in the mold. Here you see on the left small pulley, an empty

part.

It was later repaired by adding putty, too. |

|

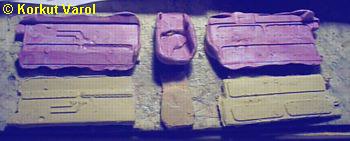

| Now coming to

the engine.. The sides were cast seperately and then joined. The purple

ones are the molds, and below them are parts cast with polyester putty. |

|

| The crankcase

and rocker covers were cast from another brand resin (fillers also used

here as seen..), and flywheel housing was cast from polyester putty. |

|

| Here the copy

is glued together and placed in front of the original. Since I bought

the

original kit assembled, I could not disassemble it to every detail,

which

made mold making harder. |

|

UPDATED

Feb.12th,2001:

The

two engines

assembled side by side in the following two pics. |

|

| The one on the

left is the copy, the other is the original. The starter motor and

lower

radiator hose are missing on the copy, they were mounted later. |

|

| The outer wheel

holder was copied with resin, this time a transparent one. The paper

clips

embedded are for rigidity purpose. |

|

|

|

|

|

|

|

|

|

|

.

.

|