| The Lynx ProjectLincoln-Mercury’s Lost Dream Car |  |

|

BUILDING THE DC-8 PLANE

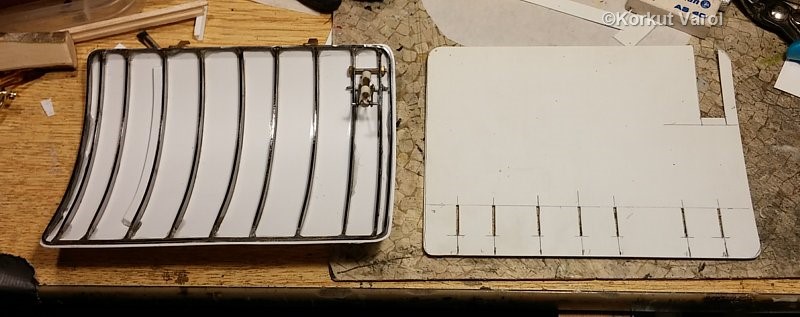

I trimmed the outer skin of the cargo door. Then I tailored the inner skin.

I began manufacturing the common actuator shaft and bearings. I cut the bearing blocks from styrene, drilled the shaft holes. Then I placed them along a 2 mm dia. rod, and trimmed all together to shape. I got all 7 bearings identical.

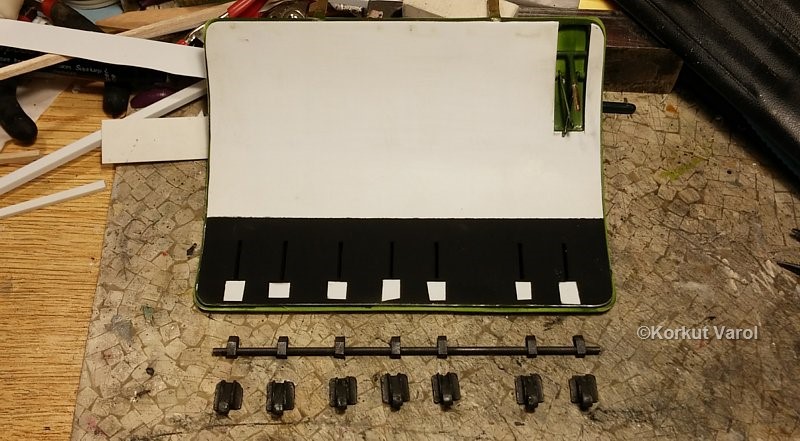

I painted the inner skin partly black (as in the original photo). I also painted the actuator shaft+bearing assembly and the lock latches dark iron metalizer.

I glued the items in place on the inner skin of the cargo door.

10 October 2014:

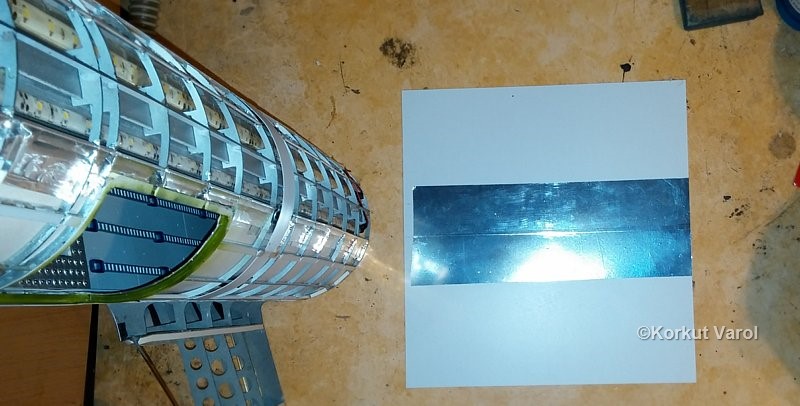

I completed the fuselage skin, then began applying polyester putty. I inserted hard paper shields in the openings to protect the insides.

| GO TO: | |||

| Lynx - index |  |  | |